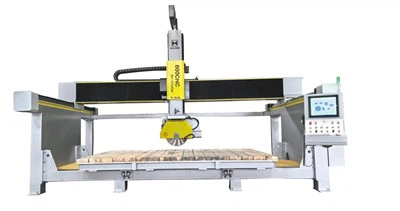

Bridge Cutter

|

Model |

4+1 Axis CNC bridge saw |

5+1 Axis CNC bridge saw |

Unit |

|

Worktable size |

L3500*W2000 |

L3500*W2000 |

mm |

|

Maximum cutting |

L3500*W2000*H90 |

L3500*W2000*H90 |

mm |

|

Maximum chamfering |

L3500*W2000*H60 |

L3500*W2000*H60 |

mm |

|

Blade diameter |

350-425 |

350-425 |

mm |

|

Main motor power |

15 |

22 (permanet magnet motor with frequency) |

kw |

|

Router power |

5.5 |

5.5 |

kw |

|

Control center |

industry computer with CNC |

industry computer with CNC |

|

|

Controller brand |

"Cut Cam" CNC System |

"Cut Cam" CNC System or ESA system from Italy |

|

|

Driving motor |

Servo motor |

Servo motor |

|

|

Router max speed |

24000 |

24000 |

RPM |

|

Total power |

28 |

35 |

kw |

|

Suction cup lifting weight |

200 |

200 |

kg |

|

Head rotate |

0°-360° |

0°-360° |

|

|

Head tilt |

0°and 45° |

0°-90° |

|

|

Cylinders |

5 |

5 |

group |

|

Dimensions |

L5750*W3260*H3500 |

L5750*W3260*H3500 |

mm |

|

Water consumption |

2 |

2 |

m³/h |

|

Total weight |

5.4 |

5.4 |

t |

|

Main part delivered size |

5750x2200x2500 |

5750x2200x2500 |

mm |

|

Machine-delivered method |

Main part delivered as a whole (HQ container) |

Main part delivered as a whole (HQ container) |

|

Price: $25,000~$40,000

|

Option: (System)

1. Self-developed CNC System with "Cut Cam"software 2. ESA System from Italy |

Option: Chassis be hot-dip galvanized |

Option: Add front sliding doors |

Option: Worktable be faced with plastic plate and rubber |

Feature

1: The machine is a conjoined structure; it takes up less space and is easy to install and move.

2: This machine has excellent four-side chamfering function and an excellent chamfering range 3500x2000mm

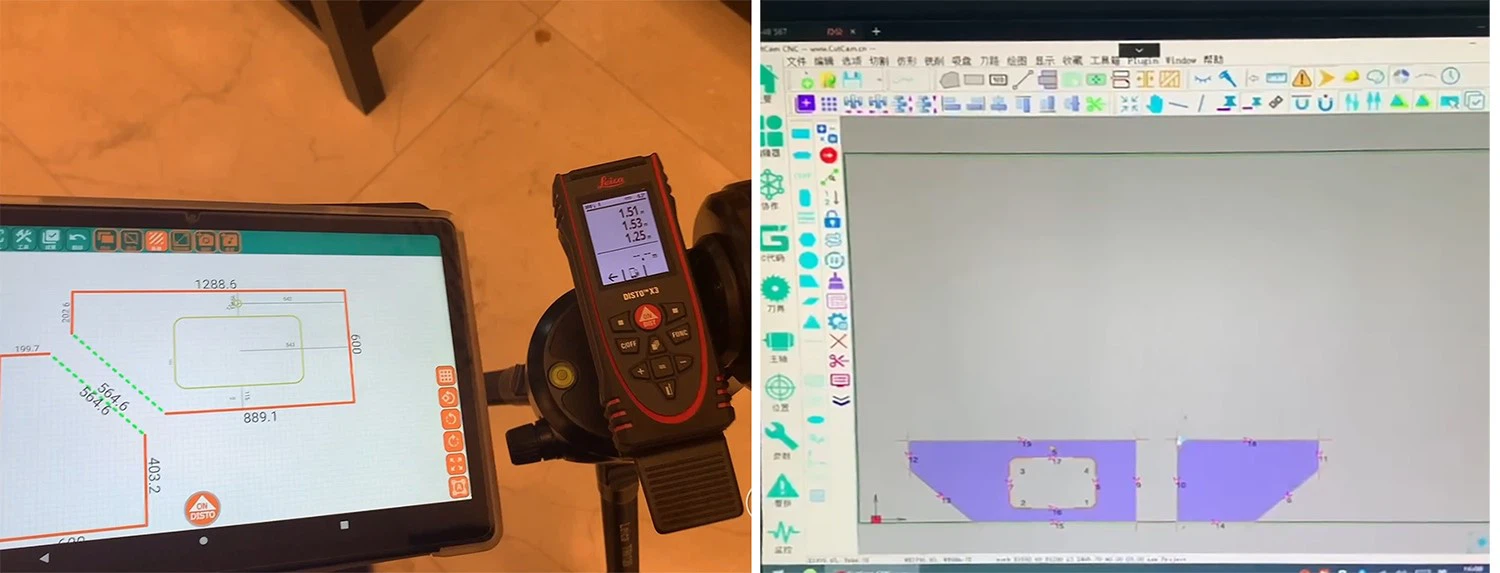

3: With an industrial computer and a 17" color touch-screen.

Option: own CNC system or ESA system from Italy

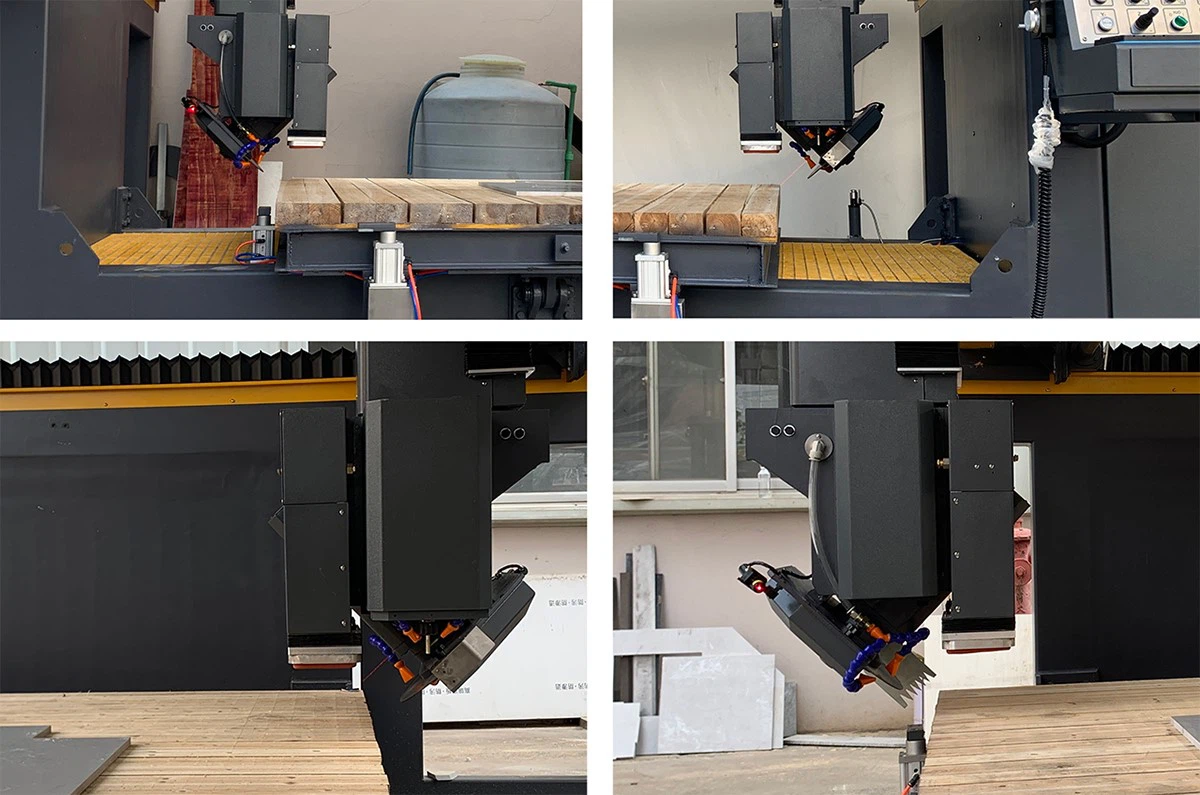

4: Use a camera to locate the position of the plate and display it in the cutting procedure.

5: The (5+1)A type with a 22-KW permanent magnet motor can be cut along with the thickness of the cutting plate, automatically adjusting the output power, strength, and power-saving environmental protection.

6: An automatic tool setting gauge is equipped that automatically checks the blade.

7. The system has a built-in library of conventional-shaped drawings and also supports DXF format imports from a designer or a countertop measuring gauge.

8: The worktable can be flipped up to 85°.

9: A group of rotating cylinders on the side of the work table will automatically press the plate when the milling cutter works and automatically withdraw after the milling cutter works.

10: Option: the machine chassis could be hot-dip galvanized, and the worktable could be faced with plastic plates and rubber.

11: Option: front sliding door.

Application Picture and Video

Shipment

Factory

Honour

The Bridge Cutter supports image planning, chamfering, and 3D shaping methods such as arc and wave line shaping. This is in addition to the usual plate-slicing. The primary component of the ZLBS-425CNC type can be totally encapsulated in an open-top high-cube container. Furthermore, after-sales support is accessible, and our professionals can assist the operator remotely. We will deliver the finest value and service.The main parts of our equipment are processed by a CNC precision machine. The key assembly process is carefully inspected, and the final product will undergo a cut stone test before leaving the factory.We try to make the quality of the product perfect for the customer, and the price is very affordable.

We also provide OEM/ODM production machine service; feel free to contact us.

The CNC Marble Cutting Machine has numerous advantages and has revolutionized the way marble cutting is done. Here are some of its benefits:

The machine has a standard 22KW permanent magnet motor, output strength, and power savings.

Precision: The CNC Marble Cutting Machine uses advanced technology and programming, making it extremely accurate and precise. It ensures that the marble stones are cut to the exact shape and size required.

Efficiency: The machine is designed to be highly efficient, saving valuable time and manpower. It can cut a large number of marble stones in a short period of time without compromising on precision or accuracy.

Consistency: The machine provides consistency in the quality of the marble stones cut. Each stone will be the same as the other, giving an equal and uniform appearance to the final product.

Versatility: The machine can cut marble stones of various sizes, thicknesses, and shapes. It can be used to create intricate designs, which would have been difficult to achieve manually.

Cost-effective: The machine is cost-effective in the long run as it reduces material waste and decreases the need for additional manual labor, ultimately saving a lot of money.

Enhanced Safety: With the CNC Marble Cutting Machine, the risk of injury associated with manual marble cutting is greatly reduced. The machine is designed with safety features that prevent accidents.

In conclusion, the CNC Marble Cutting Machine is a highly advanced and efficient machine that has transformed the way marble cutting is done. Its advantages are numerous, from precision and efficiency to cost-effectiveness and safety. It is a must-have in the industry, and its capabilities will continue to evolve and revolutionize the sector in the years to come.

Why Choose Us?

We attend the annual Xiamen Stone Exhibition, at which we will display the various functions of the machine. Every time we can attract a lot of customers to visit our machines, and there are also many customers to ask for us, and place orders for our machines, also welcome you to visit and understand.

Hot Tags: bridge cutter, China bridge cutter manufacturers, suppliers, factory, Marble Cutting Machine, Marble Machine, Marble Profiling Machine, Bridge Cutter, Bridge Cutting Machine, Marble Bridge Cutting Machine

Previous

CNC Granite Bridge SawYou Might Also Like

Send Inquiry