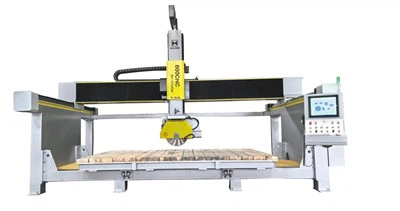

5 Axis CNC Saw

|

Model |

ZLBS-600CNC/5A |

ZLBS-600CNC/5A (special design) |

Unit |

|

Worktable size |

L3500*W2000 |

L3500*W2000 |

mm |

|

Maximum Processing |

L3500*W2000*H500 |

L3500*W2000*H800 |

mm |

|

Blade diameter |

₵350-600 |

₵350-600 |

mm |

|

Control center |

industry computer with CNC |

industry computer with CNC |

|

|

Driving motor |

Servo motor |

Servo motor |

|

|

Main motor power |

22 (permanet magnet motor with frequency) |

22 (permanet magnet motor with frequency) |

kw |

|

Total power |

30 |

33 |

kw |

|

Head rotate |

0°-360° |

0°-360° |

|

|

Head tilt |

0°-90° |

0°-90° |

|

|

worktable flip |

85° |

no |

|

|

Water consumption |

2 |

2 |

m³/h |

|

Total weight |

6 |

6 |

t |

|

Dimensions |

L5750*W3260*H4100mm |

L5750*W3260*H4100mm |

mm |

|

Delivered dimensions |

L5750xW2200xH2680mm |

L5750xW2200xH2680mm |

|

|

Delivered method |

The main part delivered as whole in a high-cube container |

The main part delivered as whole in ahigh-cube container |

|

Price: $30,000~$40,000

|

Option: (System)

1. Self-developed CNC System with "Cut Cam"software for 2D/2.5D Production 2. ESA System from Italy for 3D Production |

Option: Chassis be hot-dip galvanized |

Option: Add front sliding doors |

Option: Worktable be faced with plastic plate and rubber |

Feature

1: The machine is a heavy-duty conjoined structure; it is strong, takes up less space, and is easy to install and move.

2: With an industrial computer and a 17" color touch-screen.

3: Use a camera to locate the position of the plate and display it in the cutting procedure.

4: A 22-KW permanent magnet motor can be cut along with the thickness of the cutting plate, automatically adjusting the output power, strength, and power-saving environmental protection.

5: The system has a built-in library of conventional-shaped drawings and also supports DXF format imports from designer or countertop measuring gauges.

6: Option:The machine chassis could be hot-dip galvanized, and the worktable could be faced with plastic plates and rubber.

Application Picture and Video

Shipment

Factory

Honour

Arc and wave line shaping are two of the 3D shaping techniques available on the 5 Axis CNC saw. In addition to the customary plate-slicing, an open-top high-cube container can completely encapsulate the main component of the ZLBS-600CNC/5A type. Additionally, after-sales support is offered, and our expert may give the operator remote assistance. We'll give you the best service and value we can.This machine is standard with a 22-kilowatt permanent magnet motor, can consume the strength needed, automatically adjust the output power, has large power, and can save electricity. It is a model with advanced technology.

The 5-axis CNC saw offers several advantages over traditional sawing methods. Firstly, it allows for a higher level of precision and accuracy, resulting in more intricate and complex designs. This technology eliminates human errors and ensures consistent quality in every cut, increasing productivity and reducing waste materials.

Additionally, the 5-axis CNC saw can trim and round edges, which were previously only possible through manual labor. It saves time and labor costs, making it a more cost-effective option for businesses.

Finally, the 5-axis CNC saw is safe to use, as it eliminates the need for manual labor and reduces the risk of workplace injuries.

Overall, the 5-axis CNC saw is an innovative and superior technology that has revolutionized the sawing process, offering precision, versatility, and safety in one machine.

The 5 Axis CNC Saw is an advanced cutting machine used in the manufacturing industry. Here are ten positive features of this technology:

1. Precision Cutting - The 5 Axis CNC Saw has five axes that allow the blade to cut accurately and precisely. It can create complex cuts that are impossible to make with other machines.

2. Higher Efficiency - With this technology, you can cut more pieces in less time, leading to improved overall production efficiency and lower operating costs.

3. Versatility - The machine can adapt to various materials such as stone, metal, plastics, and composites, widening the scope of work that can be done.

4. Automation - The 5 Axis CNC Saw can run automatically, reducing the need for manual labor. Operators can focus on monitoring the process rather than the cutting process.

5. Consistency - The machine offers consistency in the cutting process for enhanced product quality.

6. Safety - Unlike other cutting machines, the 5 Axis CNC Saw has safety measures in place that minimize the risk of accidents, such as blade breakage detectors and emergency stop buttons.

7. Minimal Waste - This technology maximizes material utilization and reduces waste, therefore saving on raw material costs.

8. Durable - The machine is durable and can withstand the rigors of commercial cutting operations.

9. Customized Cutting - The 5 Axis CNC Saw can be programmed to produce customized and intricate cuts, making it perfect for creating unique products.

10. Time-Saving - The machine's speed and accuracy save time, enabling businesses to complete projects efficiently and quickly.

FAQ

Q: Are you a trading company or a manufacturer?

A: Our factory is in Taizhou, Zhejiang Province, which is one of the world's largest CNC machine production bases. The main parts provided here are very perfect, such as linear track and the servo motor. Here we can produce multi-functional high-precision five-axle bridge cutting machines.

Q: Can you do OEM and ODM?

A: We can OEM various CNC stone cutting machines for dealers around the world.Welcome to our factory for a field visit and communication. We have very good processing equipment and production processes.

Hot Tags: 5 axis CNC saw, China 5 axis CNC saw manufacturers, suppliers, factory, Stone CNC Router, CNC Stone Machine, 5 Axis CNC Saw, Stone CNC Center

Previous

CNC Granite Saw For SaleYou Might Also Like

Send Inquiry